Anodic oxidation treatments and polishing for aluminum and its alloys

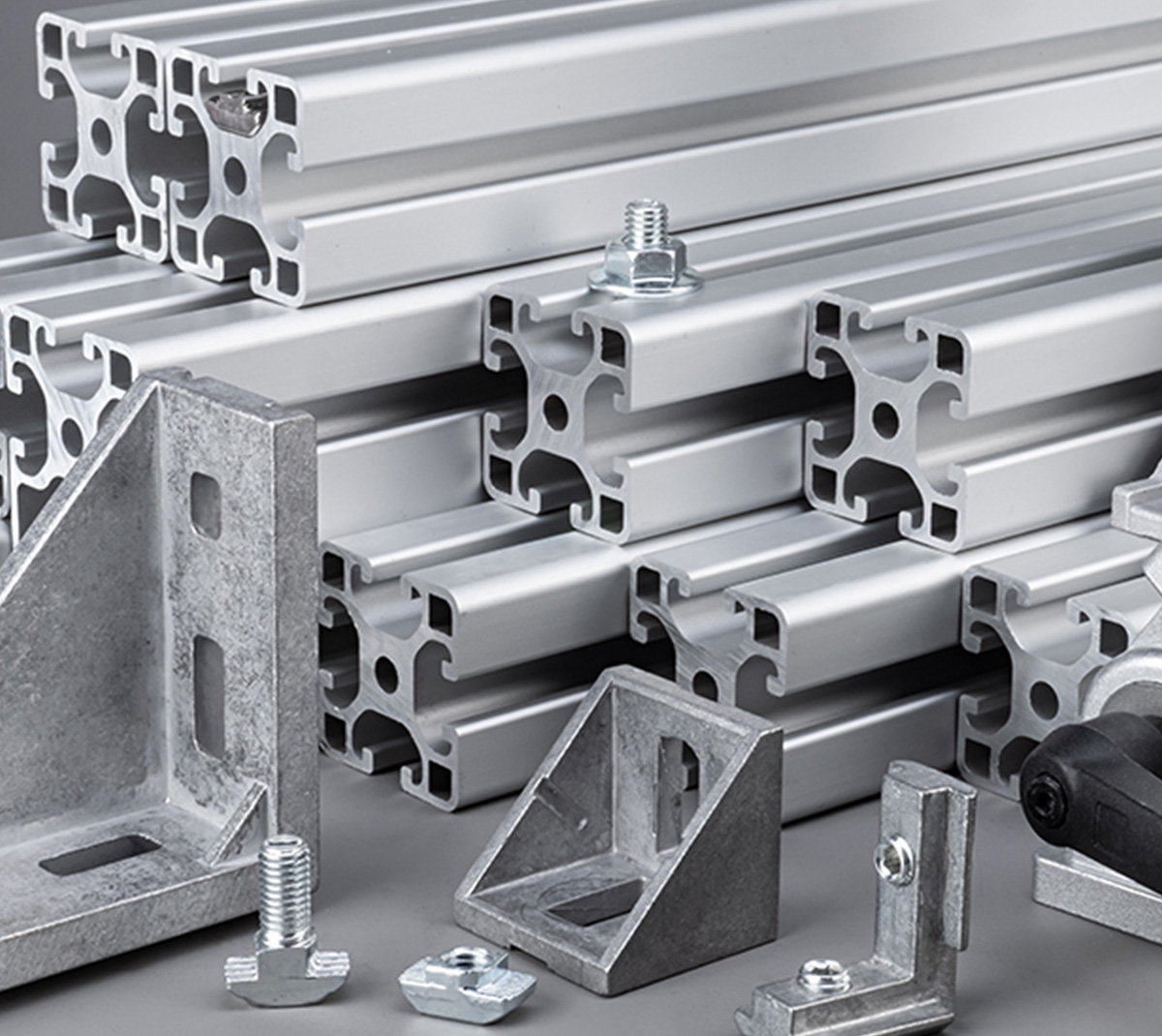

The Minicolor company offers services on behalf of third parties for assembling aluminum products and machining for various intended uses for any product category: from small metal parts for mechanical workshops to profiles for furnishings.

The company

For 40 years, Minicolor of Boltiere has specialized in the treatment of aluminum and its alloys, dealing with anodic oxidation for aluminium. It also provides aluminum polishing and coloring services, aluminum pickling and passivation, and assembly.

We carry out treatments of anodizing, pre-treatments and metal and alloy finishes

The services offered

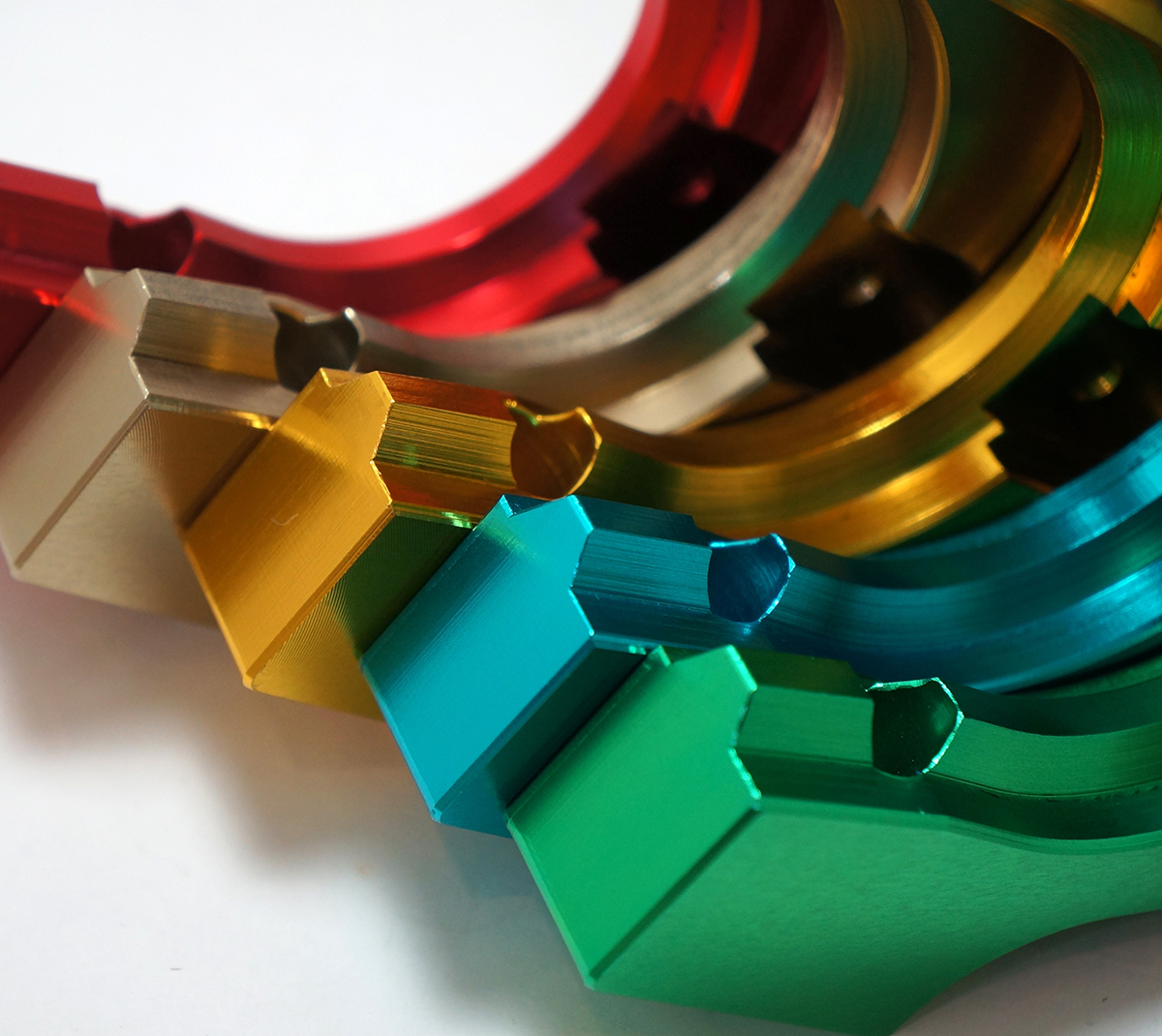

Natural and colored protective anodizing and aesthetic aluminum finishes

(thicknesses from 5 to 25 microns)

Each item used in our daily life has been studied to provide its maximum technical performance and have an aesthetic impact; the finish, the colors must enhance the product and attract the customer's interest. The aluminum finishes are different according to its applications. We offer a wide range of finishes and colors (38 shades that include the entire chromatic scale), complying with the international standards of the sector or supporting the customer in the design phase for a dedicated calibration of the treatment.

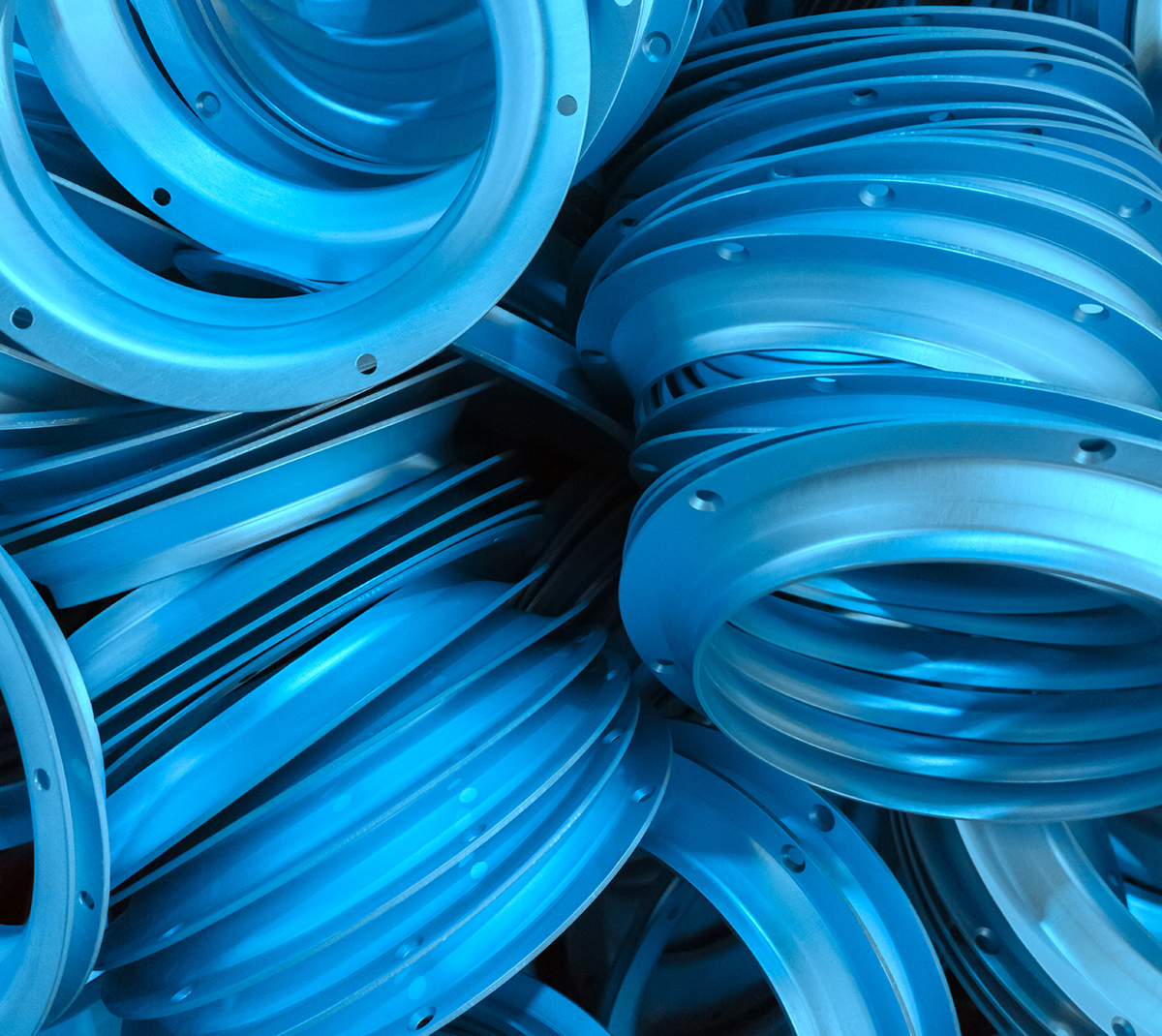

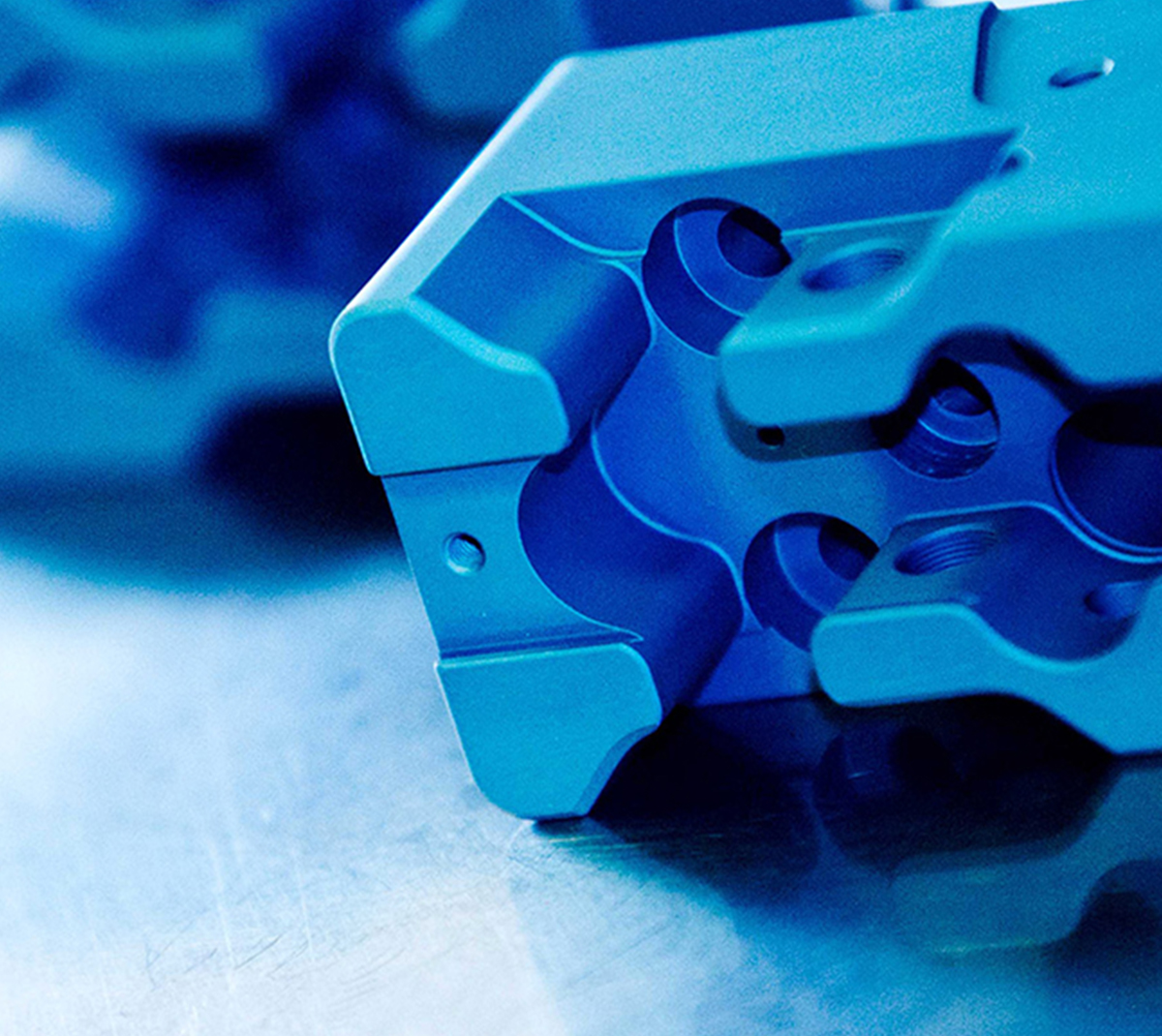

Hard and semi-hard anodizing of aluminium

(thicknesses from 25 to 150 microns)

The thick hard anodizing treatments are aimed at those details, generally intended for industrial use, which have objectives of high precision and reliability. In fact, the hard anodic oxidation of aluminum gives the particular characteristics of high surface hardness, as well as resistance to corrosion, friction, thermal and chemical resistance.

Powder Coating

Powder coating is a special technique for coating metals with a colored film for the purpose of preserving them from corrosion and decorating them. The technique of powder coating is also called electrostatic coating, the coloring pigment in the form of a powder based on synthetic resins adheres perfectly to the surfaces, thanks to the passage in the oven the high temperatures.

Chemical passivation of aluminum

Aluminum passivation chemical treatments are performed on parts that need protection from attack by chemical and atmospheric agents and from corrosion. Through this procedure, the detail develops resistance to any type of external aggression while maintaining its own characteristics of electrical conductivity at the same time.

offers services for the following markets

Railway

Industrial

Aerospace

Lighting technology

Lighting

Nautical

naval

Pneumatics

Closing

systems

Fashion and

design

Contract

Sports

technician

Automotive

Racing

Security

systems

Do you need a quote?

For information and quotes, call the number

+39 035 4195199

or contact us by filling out the form below:

Contacts

address

Via W. A. Mozart, snc 24040 Boltiere (BG)

telephone

+39 035 4195199

preventivi@minicolor.srl