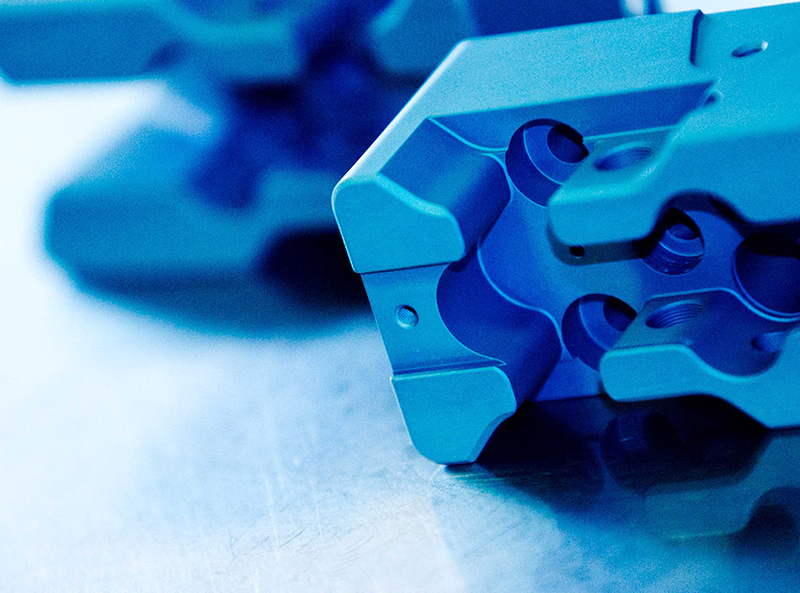

Chemical passivation of aluminum

The chemical aluminum passivation treatments are performed on parts that need protection from attack by chemical and atmospheric agents and from corrosion. Through this procedure, the detail develops resistance to any type of external aggression while maintaining its own characteristics of electrical conductivity at the same time. The passive film that is created by the treatment protects the piece and guarantees the adherence of the subsequent painting

The chemical passivations performed by Minicolor

Minicolor performs various chemical passivation treatments:

Passivation treatment with fluorzirconate: its characteristic is that it can be applied both on aluminum alloys and on magnesium alloys and in the complete absence of chromium molecules; it therefore complies with the technical specifications that require it. The appearance of the protective film that is deposited on the surface of the piece is straw yellow and therefore makes the treatment perceptible. The process, carried out in the absence of nickel, chromium and zinc, forms a layer on the surface which improves the adhesion of the paint offering greater protection against corrosion.

Chromic passivation treatment: it is a chemical passivation treatment in the presence of molecules of Chromium III. Its main feature is to provide aluminum alloy parts with greater resistance to corrosion than other passivation treatments, while maintaining electrical conductivity.

Why turn to Minicolor: advantages and applications of chromic passivation

Minicolor performs the Surtec® 650 trivalent chromic passivation treatment in the total absence of the hexavalent Chromium VI molecule and therefore complies with the RoHs directive and with the specifications and regulations of the sector. All the major production sectors, from the automotive to the military, have approved the Surtec® 650 treatment for the specifications of their products. The treatment has a colorless or bluish-tinged finish and can vary according to the thickness of the treatment layer and the alloy used. Also in this case, the adhesion of the subsequent painting, where present, is guaranteed.